Right from the time the wheel was invented, all the things that man has created has a rationale behind it. Almost all the manmade objects that we see around us have an engineering design component in it. Take the simple example of a spoon. It can come in different sizes and material, but the basic utility remains unchanged. While the aesthetics may differ, there is an engineering design component in a spoon that makes it useful to serve / eat food.

The importance of Engineering Design

While the spoon is a very basic example, the complex artifacts that humans make today invariably involve engineering design. The Worli Sea link in Mumbai, the fastest car in the world, the supersonic jets, smart phones, the Burj Khalifa and the latest innovation in diagnostic medicine - all are examples of engineering design at work.

Engineering design is the use of scientific principles, technical information and imagination in the definition of a mechanical structure, machine or system to perform pre-specified functions with maximum economy and efficiency. The fundamental elements of the design process include the establishment of objectives and criteria, synthesis, analysis, construction, testing and evaluation.

Thus, the prime purpose of engineering design is to apply scientific knowledge to the solution of technical problems. While engineers provide a technical solution, it is very important to understand that engineering design implies a solution that is aesthetic as well. In other words, designers too are involved to ensure that the end product is economical, eco friendly and appeals to users.

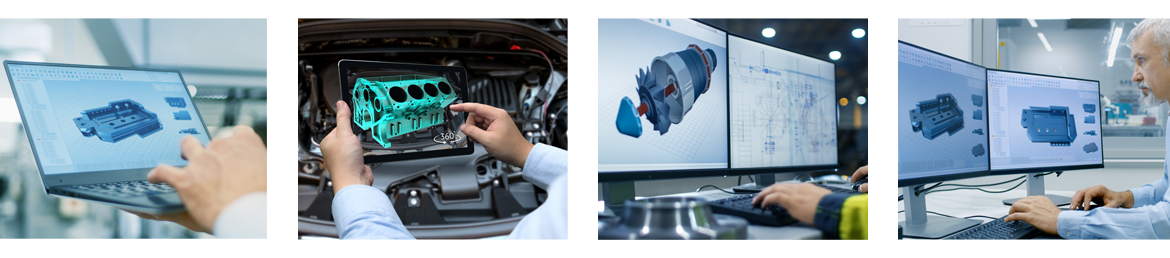

Engineering Design Tools

Many tools are available today that helps engineers / designers achieve their objective. Computer Aided Design (CAD) and Computer Aided Engineering (CAE) are software that allows engineers to be creative while satisfying the technical requirements of a product. A few of the popular tools include PTC Windchill, CAE Suite of Solutions from Altair, 3D printers from Stratasys, MATLAB and SIMULINK from MathWorks .

Introduced in the 1960’s to automate the task of design engineering, these tools have now grown phenomenally in terms of sophistication and functionality offered. Often time, special training is required to use these tools correctly.

Engineering Design Services

Because modern technology is so complex, it is now near about impossible for an individual to handle design and development of a new product single handedly. It takes a team of designers and engineers to successfully manufacture a new product. In order to achieve success, the design process must be planned carefully and executed systematically. Specifically, the engineering design process must integrate the many different aspects of designing in such a way that the whole process becomes logical and comprehensible. In addition, most of the CAD / CAE software available today is complex. It takes special training to understand and utilize the harness the real power of these applications. Secondly, the cost of acquiring these tools is rather expensive. Many companies that need to develop products therefore outsource their engineering design requirements to agencies that provide such services. There are also times when the company has trained manpower and good CAD / CAE infrastructure, but the people working there are simply overloaded with work. In such cases too, companies avail engineering design services to share their work load when they are hard pressed for time.

A few of the engineering design services include :

- CAD design services

- CAE design services

- FEA services

- Moldflow Services

- Thermal Analysis Services

- CFD services

- Structural Analysis Services

- Noise and Vibration Analysis Services

- Kinematics and Multibody Dynamics Services

In developing nations (like India), engineering design services are the need of the hour. There are many small and medium scale industries that do not have the necessary infrastructure to thoroughly evaluate their product ideas and reach the manufacturing stage, and reputed design services companies are in good demand to assist them.

Also read: Engineering Design Services – Today’s Need