- is useful in developing products

- blends engineering knowledge with creative design

- requires professionalism

- needs special skills and tools

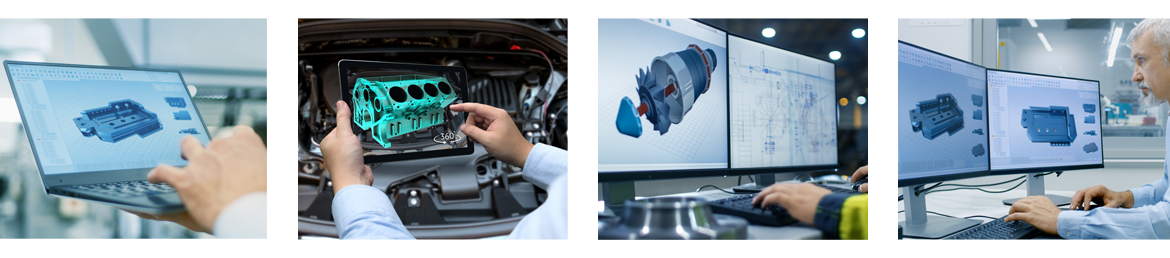

Today, the emphasis is on ‘usability’ coupled with attractive packaging. No longer are people satisfied with a functional product; they also want it to be appealing. As CAD and CAE tools get more complex and more powerful, it takes special expertise to properly use these tools and exploit their potential. This need has resulted in a demand for companies that offer engineering design services.

Steps in Engineering Design Services

Once an entrepreneur / company decides to go ahead with a product / artifact, the next step is to approach a professional engineering design services provider. Since a product designing can have a multitude of answers, there usually is an iteration involved in the design process. The design service company will handle all these cyclic iterations. Here are the basic steps that any engineering design services provider undertakes:

1. Identifying the design needs

This process usually contains a listing of the product function and the customer requirements and expectations about the product features.

2. Gather relevant information about the product / artifact

A lot of research goes in this step. It can involve studying the competitors’ products, reading of books / browsing the internet for similar products and talking to potential consumers. This step also involves identifying the loads, boundaries, conditions and forces that will be applied on the product. The product design should be such that it facilitates the smooth functioning of the product’s purpose under the hardest of the conditions. At the same time, the design should be optimized and should be appealing.

3. Brainstorm about possible solutions

Since design engineering is a mix of science and creativity, there can be more than one solution for a product development. The engineering design services team discusses various options that would result in the best possible artifact. It is also important to ensure that the costs and time of development are kept to the minimum. This necessitates getting the product design right the first time.

Today’s advanced CAD software is intuitive and suggestive. They also contain a standard design/ or parts library which can help designers meet necessary standards and norms of design. CAE software solutions help the engineering design service team virtually analysis and simulate product designs that highlight weak areas in the design which when corrected help companies develop robust product designs.

4. Zero in on the most feasible solution

After exploring all the “What if” scenarios, the companies can narrow down on the design they wish to go ahead with.This step involves selection of the best possible solution that best meet the requirements of the product / consumer and modelling a prototype using CAD / CAE software

5. Implement and test the design solution

The advent of 3D Printers has made prototyping easy. Most companies that provide engineering design services use a 3D printer to actually create a 3D object. It is then tested extensively. Creating a physical model helps companies validate the product functioning, fit, form and ergonomics. This further helps enhance product design performance.

The above steps are iterated till a satisfactory engineering and design solution is achieved.

Design engineering is the driving force behind every product created for customers. Companies that specialize in this field offer value-added services that are customized to the customer's needs.

Since proper design engineering is the foundation of a successful product – be it a household object or a complex architectural marvel, it is important to choose a company that has ‘hands on’ experience in providing these services.

You may also like to read: